Delivery Inspection

Crumpler Plastic Pipe, Inc. makes every effort to ensure order accuracy and quality. As a final check, the customer should conduct a personal inspection at delivery to verify that the correct product and the expected quantity is received. Pipe corrugations, gaskets, pipe ends, couplers or other joints, and any accessories should be visually inspected for damage that may have occurred during shipment.

Product Identification

Product markings on Crumpler Plastic Pipe will include the following information to facilitate job-site inspection.

- Nominal pipe size

- Manufacture’s name

- Date code

- Applicable standard(s)

Unloading

The Contractor should set aside an area for products to be stored onsite. This area should be flat, free of large rocks, rough surfaces and debris. It should also be out of the way of construction traffic. Pipe may be delivered either palletized or loose, depending on the type and quantity of product. Pallets maybe unloaded with a backhoe, forklift or other piece of equipment and nylon sling or cushioned cable. The sling should be wrapped around the pallet at the third points as it lifts the pallet onto the ground. As an alternative to using a sling to unload full pallets, the pallet maybe opened and lengths of pipe unloaded individually by carefully rolling single lengths of loose pipe from the delivery truck onto the front-end loader, then onto the ground. Alternately, the pipe can also be lifted using a nylon sling or cushioned cable at the third points.

Weight of Individual Joints of Pipe

Pipe Dia.

12”

15”

18”

24”

30”

36”

42”

48”

Length

20′

20′

20′

20′

20′

20′

20′

20′

Weight

70 lbs.

107 lbs.

150 lbs.

235 lbs.

300 lbs.

360 lbs.

470 lbs.

580 lbs.

End handling with a forklift should not be used, as pipe damage will occur. Due to joint weight, larger diameter pipes should not be off loaded by hand.

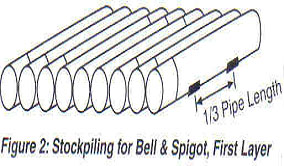

Job Site Storage

Reasonable care should be used in handling pipe. The pipe should not be dropped, dragged or bumped against other pipe or objects. Palletized pipe should remain in the pallet for jobsite storage. Non-palletized pipe can be stockpiled for temporary storage in a flat debris free area out of the way of construction traffic. Begin the stockpile with secured timbers spaced the width of the proposed stockpile at a distance not exceeding the third points. For pipe with attached bells, a recommended stacking method is to alternate the direction of the pipe lengths so that the bells are not stacked on each other. As shown in Figure 2, up to three pipes can be laid before alternating directions. Subsequent layers should follow that same pattern as the first but with fewer sticks of pipe in each row. For smooth interior pipe, storage space can be minimized by nesting smaller diameter pipe. Factory installed gaskets on the spigot should be protected by positioning them between corrugations.

Stringing the Pipe

Placing the pipe and accessories along the open trench, or “stringing,” can save handling time. Each pipe length should be laid on a level surface as near as possible to the trench on the side opposite the excavated trench material; allow some space between pipe to protect pipe ends. The pipe should be out of the way of any equipment in a location that will allow excavation to proceed uninterrupted.